Maintenance of Synthetic Sports SurfacesWhile the use of synthetic sports surfaces has grown significantly, in some quarters the misconception remains that they require little or no maintenance. Dr Colin Young explains, however, that not only is this detrimental to their playing quality but it also reduces the effective benefit of the investment

Maintenance is of vital importance if a sports surface is to remain good to look at, to perform consistently at the required standard, to retain its permeability and last a long period of time. Indeed, the surface’s guarantee will usually be conditional on the maintenance requirements being carried out with reasonable diligence. Maintenance is of vital importance if a sports surface is to remain good to look at, to perform consistently at the required standard, to retain its permeability and last a long period of time. Indeed, the surface’s guarantee will usually be conditional on the maintenance requirements being carried out with reasonable diligence.The recommendations of the surface installer/manufacturer should be followed at all times as they will have the best knowledge of their specific product and its specific needs. Companies should always provide clients with a handbook (operations manual) outlining the particular maintenance requirements of their surface. Maintenance processes will differ between surface types but the basic principles and objectives are the same:

Maintenance requirements will differ according to the type of surface and its usage. The usage of a facility should be carefully planned to ensure one particular area is not overused, such as the goal mouths of a football pitch or the inside lanes of a running track. Whilst this is sometimes unavoidable care should be taken to use the facility evenly as far as possible. If some areas are used more frequently than others, the maintenance at these locations should reflect these variations. The groundstaff should be consulted on a regular basis as they will understand how the surface is used and be able to identify areas of concern.

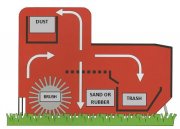

There are different types of maintenance that can be carried out on the surface, ranging from routine cleaning and brushing to more advanced treatments requiring specialist equipment and chemicals. Routine maintenance can be conducted by the groundstaff but more advanced procedures are often undertaken by specialist companies with bespoke advanced equipment which can add new life to an ageing facility.

|

|  |  |  |