An overview of some of the main principles and types of maintenance.Keeping the surface cleanLeaves, tree flowers, pine needles, dirt from users and other detritus should not be allowed to remain on the surface for any length of time. If this does happen, they rapidly rot down to form a drainage-inhibiting ‘skin’ within the surface and provide a growing-medium for algae and moss. A wide, soft broom or a rubber-tined rake is ideal for removing vegetable matter and other rubbish. Better still, a mechanical leafsweeper or vacuum cleaner will greatly speed up the operation. The equipment should be well maintained and carefully operated to avoid contamination of, or physical damage to, the surface.

The provision of litter bins and an information board outlining key ‘do’s and don’ts’ will also help to keep the surface clear of rubbish brought on by users. It is strongly recommended that the surface should be treated as a ‘no smoking’ area, as a dropped cigarette can damage the surface resulting in unsightly marks. Chewing gum should also be banned for this reason.

BrushingBrushing the surface is a crucial operation if premature deterioration of the playing characteristics, appearance and drainage properties are to be prevented. Apart from freshening up the look of the surface, the purpose of regular and fairly vigorous brushing is to prevent the formation of a compacted and impervious skin on the top of the surface. This is especially noticeable on a synthetic turf surface with a sand, clay or rubber infill.

By constantly disturbing and moving the upper layers of the surface, brushing can delay by several years the time when problems of reduced drainage start to develop. It is common to use a drag brush which is pulled by a small tractor unit with low-pressure tyres.

Power Brushing and DecompactionThis is a common procedure, and the principle involves the use of a powered brushing machine, often with contra-rotating brushes, which ensures that the synthetic turf fibres remain upright and the infill remains mobile within the surface. This is normally undertaken by specialist companies; its frequency depends on the amount the surface is used and its surrounds. This could be as much as monthly for very high-usage facilities or just annually for much less well-used surfaces.

Deep and Power CleaningIf, in spite of the regular maintenance described, or as a result of a lack of it, a surface becomes dirty or in the case of synthetic turf over-compacted and impervious, these conditions can often be corrected by appropriate treatment involving the use of specialist machinery. The type of cleaning will depend on the surface type.

Polymeric surfaces (and some macadam surfaces) will require cleaning with high-pressure jetting apparatus which might include detergent and fungal inhibitors to remove dirt and prevent moss and algae growth.

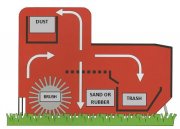

Synthetic turf surfaces require different machinery depending on their design. Generally machines vary from simple scarifiers to more elaborate proprietary machines that remove a proportion of the infill (containing almost all the filtered dirt) from the upper part of the synthetic turf. This is then replaced with new (or cleaned) infill.

The best of these processes will improve the play characteristics, ball roll and surface/foot interaction and will prolong the useful life of the pitch by a number of years. It is essential that any scarification or very deep penetration of the surface is only carried out by experienced operatives and, if still under warranty, approved by the installer or surface supplier.

The long-term benefits of maintenance are well understood but all too often little provision is devoted to it. Maintenance should be budgeted from the outset of a new project and included in the business plan and sinking fund provision. It should start from the first day after handover of any new facility. The roles and responsibilities should be clearly identified including in-house provision and the role of specialist companies as required. The groundstaff should be consulted on a regular basis and, if required, trained to use new equipment.

|

|  |  |  |